Thermal Grizzly Intel Lga1851 V1 Delid Die Mate

1 EGP

- Color: Black, Red

- Material: Aluminum

- Socket Manufacturer: Intel

- Socket Type: LGA 1851

Out Of Stock.

رمز المنتج: 4260711991097

التصنيفات: AIR & LIQUID COOLING, Cpu Bracket

الوسوم: Thermal Grizzly, cooling, Delid, intel, Die Mate, CPU, LGA1851, V1

العلامة التجارية: THERMAL GRIZZLY

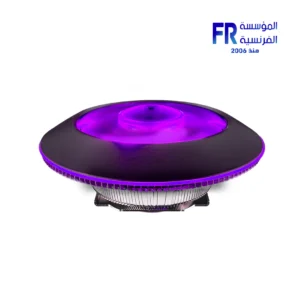

Thermal Grizzly Intel Lga1851 V1 Delid Die Mate

Thermal Grizzly Intel Lga1851 V1 Delid Die Mate SPECIFICATIONS:

- Color: Black, Red

- Material: Aluminum

- Socket Manufacturer: Intel

- Socket Type: LGA 1851

Overview

The Intel 1851 Delid-Die-Mate V1 is a specialized tool designed to safely remove the Integrated Heat Spreader (IHS) from Intel processors in the Intel Core Ultra 200 series (LGA1851 socket). By removing the IHS, users can implement the Direct-Die cooling method , where the CPU cooler is mounted directly onto the processor die. This eliminates the IHS from the thermal path, significantly improving heat transfer and reducing operating temperatures.

Key Features

- Compatibility : Designed for Intel Core Ultra 200 series CPUs (LGA1851 socket).

- Purpose : Facilitates safe removal of the IHS for Direct Die cooling setups.

- Material : Constructed from durable aluminum , ensuring stability and precision during delidding.

- Optimized Cooling : Enables up to 10-15°C lower temperatures when paired with high-performance thermal interface materials like liquid metal (e.g., Conductonaut).

Technical Specifications

- Processor Compatibility :

- Intel Core Ultra 200 Series (LGA1851 socket).

- Functionality : Removes the IHS to enable Direct Die cooling, bypassing the stock heatspreader for improved thermal performance.

- Material : Aluminum construction for durability and ease of use.

Why Delidding & Direct Die Cooling?

- Soldered Processors : Intel Core Ultra 200 series processors use indium solder between the dies and IHS. Replacing this solder is impractical due to the large gap it would create, making delidding for Direct Die cooling the preferred approach.

- Improved Heat Transfer : Direct Die cooling reduces thermal resistance by mounting the CPU cooler directly onto the die, bypassing the IHS.

- Temperature Reduction : Studies and real-world testing have shown temperature reductions of 10-15°C when using liquid metal as TIM.

Challenges with Intel Core Ultra 200 Heatspreaders

- Thermal Bottleneck : The stock IHS can act as a thermal bottleneck, limiting the efficiency of heat dissipation.

- Direct Die Advantage : Removing the IHS allows for direct contact between the cooler and the die, maximizing thermal performance.

Safety Enhancements

-

Heating Requirement : To minimize mechanical stress during delidding, the CPU should be heated to 165°C (the melting point of indium is 157°C ) to liquefy the solder and allow for easier separation of the IHS.

-

Warning Instructions : Careful adherence to safety guidelines is critical to avoid damaging the delicate CPU die.

Important Notes

-

Delidding Risks : Removing the IHS (“delidding”) is performed at your own risk and voids the manufacturer’s warranty . Any damage caused by delidding is not covered by the manufacturer.

-

Direct Die Cooling Precautions : Direct Die cooling requires careful handling to avoid damaging the CPU die. Ensure proper alignment and secure mounting of the cooler.

Use Cases

-

Enthusiast Builds : Ideal for overclockers and enthusiasts seeking maximum thermal performance through Direct Die cooling.

-

Custom Cooling Loops : Perfect for users building custom water-cooling setups with improved heat dissipation.

-

High-Performance Workstations : Suitable for professionals running intensive workloads, such as video editing, 3D rendering, and scientific simulations.

Safety and Warranty Disclaimer

-

Warning : Installation and use of the Delid-Die-Mate require technical expertise. Mishandling may result in permanent damage to the processor.

-

Warranty Void : Delidding and replacing the IHS invalidates the manufacturer’s warranty. Proceed at your own risk.

-

Disclaimer : Always follow the provided instructions carefully and ensure proper safety precautions are taken.

يسمح فقط للزبائن مسجلي الدخول الذين قاموا بشراء هذا المنتج ترك مراجعة.

المراجعات

لا توجد مراجعات بعد.