Thermal Grizzly Lapping Tool

1 EGP

- Color: Clear

- Material: Acrylic

- Socket Manufacturer: Intel

- Socket Type: LGA 1700

Out Of Stock.

SKU: 4260711990649

Categories: Liquid Cooler, AIR & LIQUID COOLING

Tags: PERFORMANCE, Thermal Grizzly, Lapping Tool, Surface Refinement, cooling, CPU

Brand: THERMAL GRIZZLY

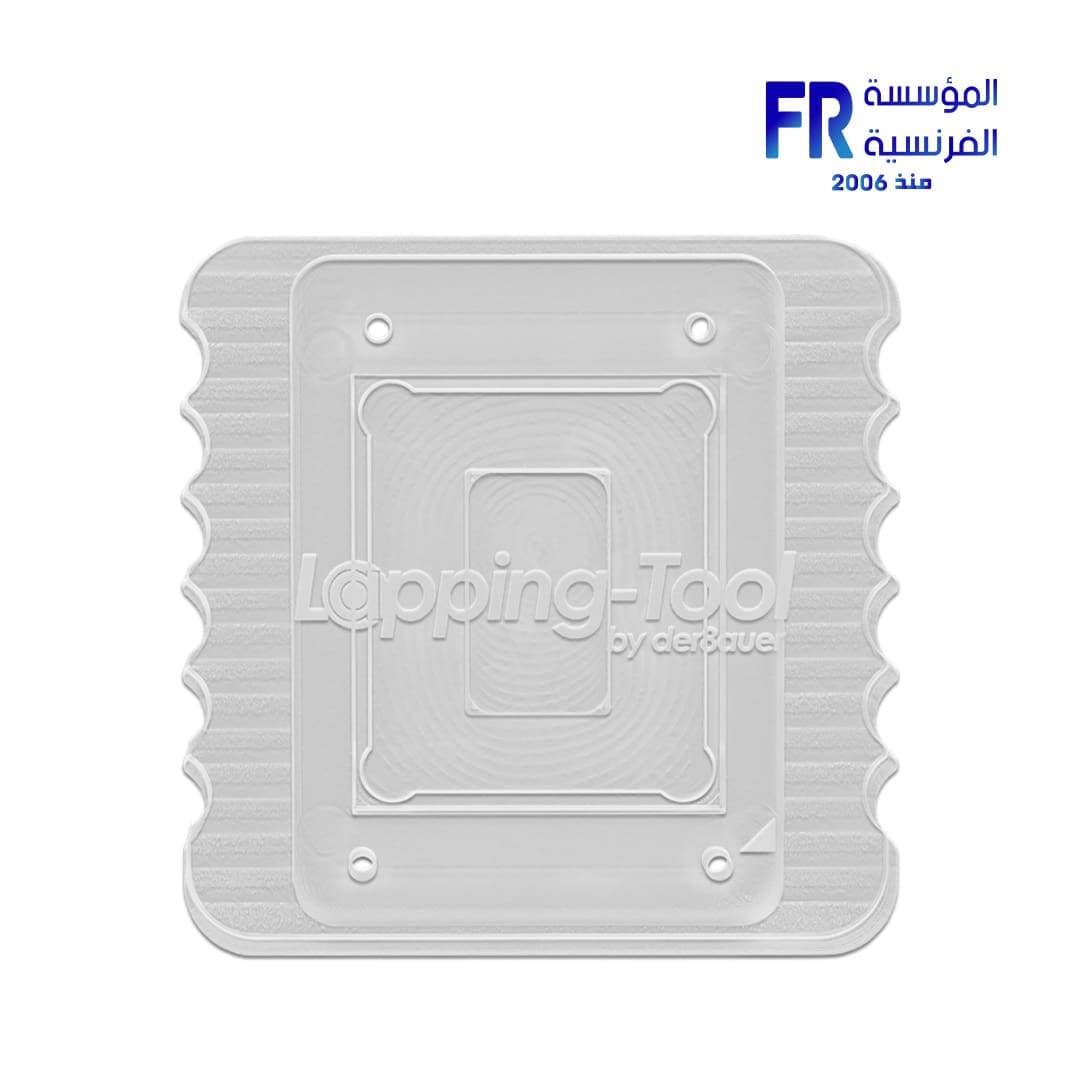

Thermal Grizzly Lapping Tool

Thermal Grizzly Lapping Tool SPECIFICATIONS:

- Color: Clear

- Material: Acrylic

- Socket Manufacturer: Intel

- Socket Type: LGA 1700

Overview

The Lapping-Tool for Intel 12th Gen processors is a precision-engineered tool designed to simplify and optimize the process of lapping (grinding) the heatspreader (IHS) of compatible CPUs. By simulating the CPU’s final position in the socket using the Intel 12th Gen Contact Frame, this tool ensures accurate and safe grinding. The goal is to flatten the IHS, improving thermal contact with the CPU cooler and enhancing overall cooling performance.

Key Features

- Compatibility : Designed specifically for Intel 12th Gen processors when used with the Intel 12th Gen Contact Frame .

- Material : Constructed from CNC-milled acrylic glass , ensuring high precision and durability.

- Tolerances : Allows controlled removal of up to 0.2 millimeters of material from the heatspreader.

- Precision Grinding : Includes sandpaper of varying grit sizes (400, 1200, 2500) for progressive lapping.

Scope of Delivery

- 1x Lapping-Tool

- 4x Screws

- 1x Wrench

- 1x Sandpaper (400 Grit)

- 1x Sandpaper (1200 Grit)

- 1x Sandpaper (2500 Grit)

How It Works

- Mounting the CPU : Secure the processor onto the Lapping-Tool using the provided screws and the Intel 12th Gen Contact Frame. This simulates the CPU’s final position in the motherboard socket.

- Sanding Process : Use the included sandpaper in sequence (400 → 1200 → 2500 grit) to progressively lap the heatspreader.

- Stopping Point : The tool is designed to allow a maximum of 0.2 millimeters of material removal. If the acrylic glass begins to wear down, stop immediately to avoid damaging the Contact Frame.

Benefits

- Improved Thermal Performance : Flattening the heatspreader enhances thermal contact with the CPU cooler, reducing operating temperatures.

- Precision Design : CNC-milled acrylic ensures consistent results and prevents over-sanding.

- Professional Collaboration : Developed with input from renowned overclockers like Roman “der8auer” Hartung and Allen “Splave” Golibersuch , ensuring reliability and effectiveness.

- World Record Achievements : Used by Allen “Splave” Golibersuch to achieve two world records, demonstrating its potential for extreme performance tuning.

Why Sanding/Lapping?

- Factory Imperfections : Heatspreaders are often slightly curved due to manufacturing processes, which can reduce contact with the cooler’s base plate.

- Enhanced Cooling : Lapping flattens the heatspreader, improving thermal transfer and reducing CPU temperatures.

- Controlled Removal : The tool allows for precise material removal of 40-150 µm , balancing performance gains with safety.

Technical Specifications

- Processor Compatibility : Intel 12th Gen processors (requires Intel 12th Gen Contact Frame).

- Maximum Material Removal :

- 0.2 millimeters (before acrylic wear begins).

- Recommended removal: 40-150 µm for optimal results.

- Material : CNC-milled acrylic glass.

Use Cases

- Enthusiast Builds : Ideal for overclockers seeking to lower CPU temperatures and improve thermal efficiency.

- DIY Modifications : Suitable for advanced users performing custom modifications to maximize cooling performance.

- Extreme Overclocking : Proven to support record-breaking overclocking achievements when combined with proper cooling solutions.

Important Notes

- Single Use Recommended : The Lapping-Tool is designed for a single use due to wear during the sanding process.

- Warranty Void : Grinding the CPU will invalidate the manufacturer’s warranty. Proceed at your own risk.

- Cooler Base Preparation : For optimal results, it is recommended to also lap the base plate of the CPU cooler.

Safety and Warranty Disclaimer

- Warning : Lapping the CPU heatspreader is an advanced procedure that carries inherent risks. Mishandling may result in permanent damage to the processor.

- Warranty Void : This process invalidates the manufacturer’s warranty, and any resulting damage is the user’s responsibility.

- Disclaimer : Always follow the provided instructions carefully and ensure proper safety precautions are taken.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.